This article understands the bleeding position setting of various printed matter

Time:2023-03-08

Views:1006

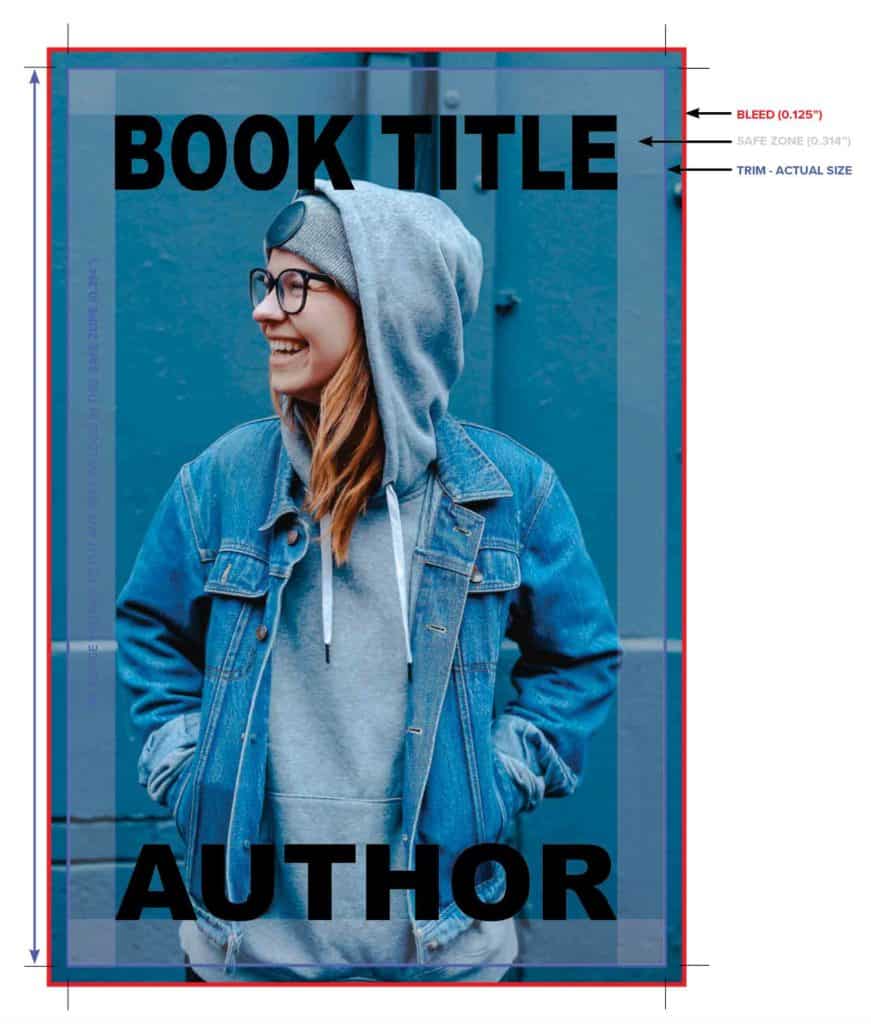

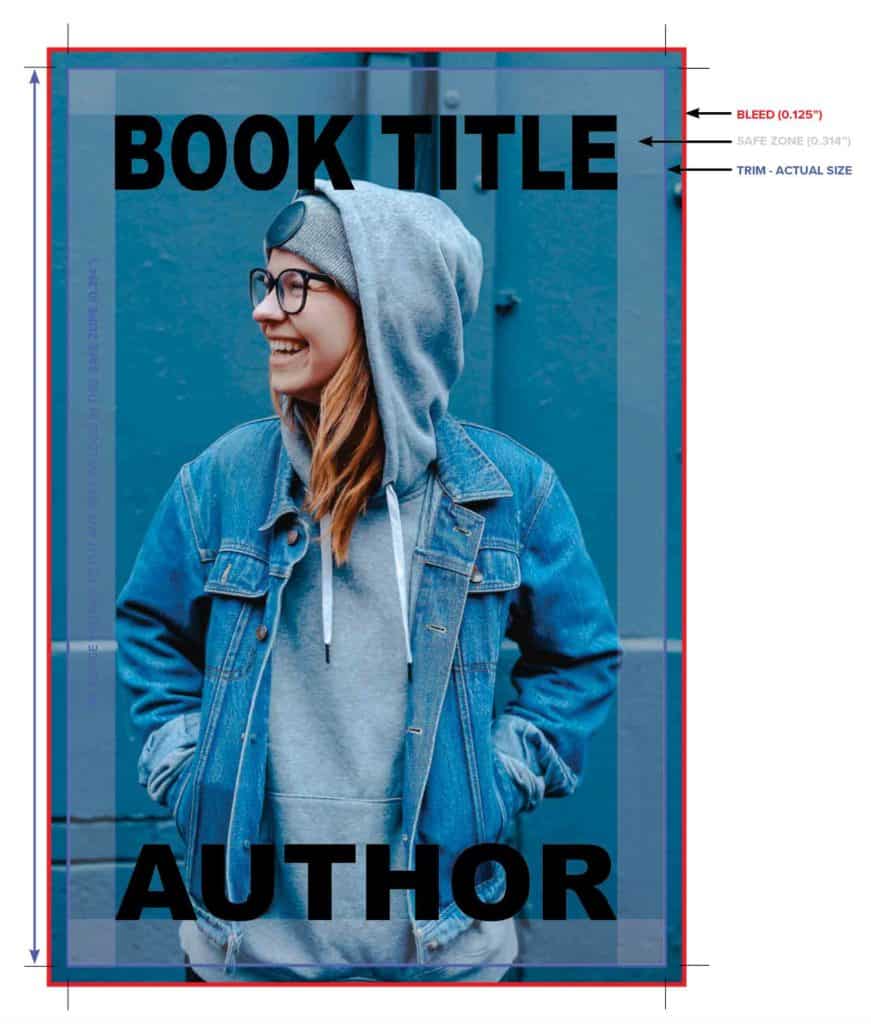

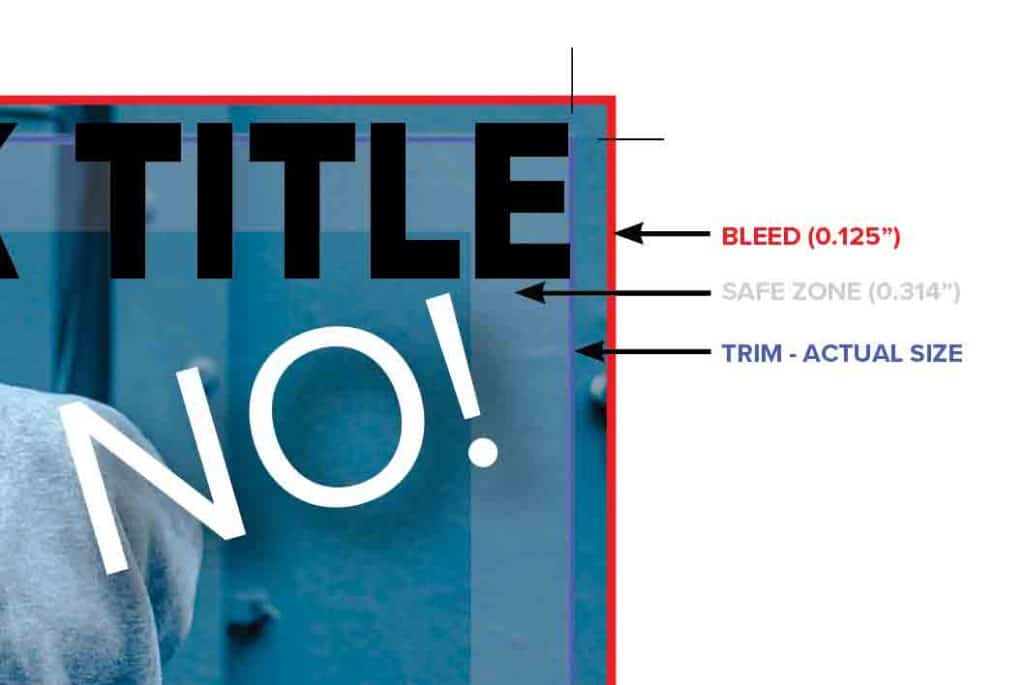

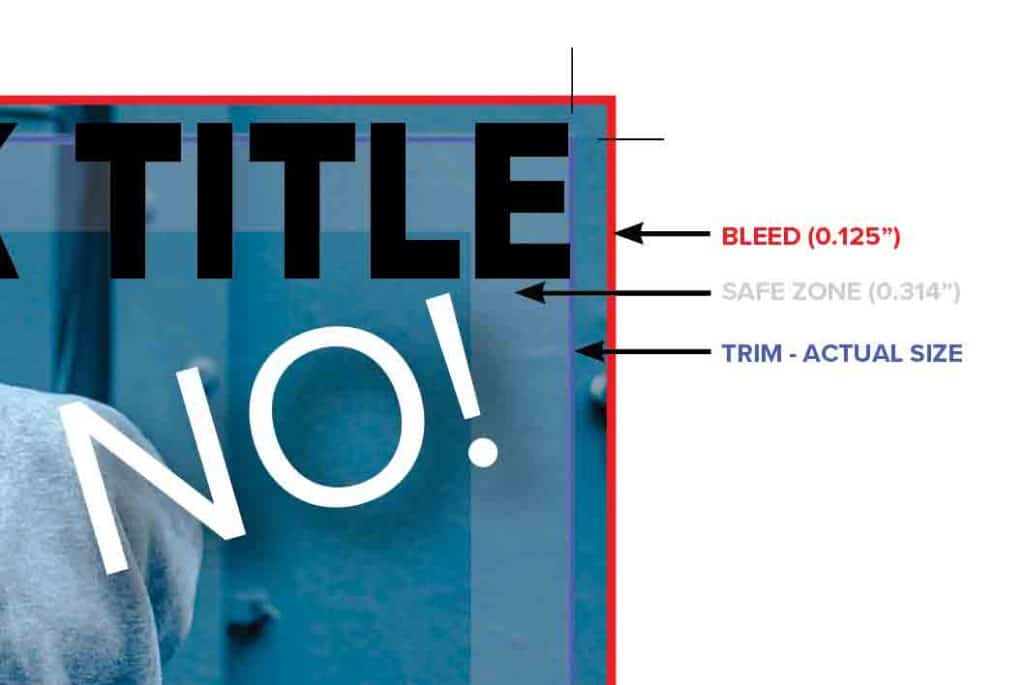

Bleed point (actually "first cut") refers to the part of the printing screen reserved for easy cutting to preserve the effective content. Bleeding in printing refers to increasing the pattern of the outer size of the product, adding some extension of the pattern at the cutting position, which is specially used for each production process within its process tolerance range, so as to avoid the white edge or the content of the finished product after cutting.

.gif)

At the time of production, we are divided into design size and finished product size. The design size is always larger than the finished product size, and the big edge is to be cut off after printing. The part to be printed and cut off is called bleeding or bleeding position.

Bleeding location

Bleeding location

1. To cut the printing must be made blood and cutting lines;

2. Business card size of the finished product, must do 2mm bleeding, double-sided printing must be positive and negative cutting lines;

3. More than the size of the finished product, must do 3mm bleeding;

4. Machine cutting, must do 2mm~3mm bleeding (new note: if the background color is the same, can also be cut);

5. Manual cutting must be done.

Various books bleeding reference

Various books bleeding reference

1. The glue book must be made white in the back of 2, 3 and 5mm of the back, and do 3mm bleeding;

2. The middle line of the horse must not make blood;

3. The cover of the iron ring and the rubber strip must be surrounded by 3mm bleeding;

4. Text hardcover: width on the basis of the finished size of the inner core must be added 3mm, height on the basis of the finished size of the inner core unchanged, back on the basis of the thickness of the inner core must be added 5mm, soft back must be done 10mm, bleeding must be done 10mm~20mm;

5. Iron ring inner hardcover: width on the basis of the finished size of the inner core plus 6mm, height on the basis of the finished size of the inner core unchanged, back according to the thickness of the inner core (consulting post-press service), soft back must do 6mm, bleeding must do 10mm~20mm;

6. Iron ring outside hardcover: width on the basis of the finished size of the inner core must be added 6mm, height on the basis of the finished size of the inner core unchanged, bleeding must be 10mm~20mm.